MATERIALS FIRST

With the emerging labor shortage, the majority of the construction industry is focusing on labor and productivity more than ever. To address the challenges the industry is facing focusing on labor or productivity only is not sufficient. It is simply impossible to build or install without materials, so materials are key to labor, project, and supply chain success. Though, planning with and around materials has been mostly overlooked. Materials are foundational for supply chains to function efficiently, and an efficient supply chain translates to timely project completion. In our previous blog, we talked about the ‘Materials First’ approach to digitizing the construction supply chains, and in this blog, we explain what ‘Materials First’ means and why it is needed.

What is ‘Materials First’?

Demand and supply are the two pillars of any supply chain. They both have multiple activities that determine the faith of a supply chain and a construction project. Materials flowing throughout the chain are foundational for both supply and demand. In a construction supply chain, design and engineering determine the demand by defining the material quantities through quantity takeoff, and the timeline for ordering based on project scheduling and deadlines. This demand information is also critical for ‘supply’ to be functional. With accurate and transparent demand information, materials could be stocked, released, and delivered in tandem with the construction project planning. As a result, successful supply chains that focus on planning for materials first lead to successful construction projects.

“We’re seeing more planning, with contractors looking days [or weeks] ahead”

David Moeller, Director of Customer Markets for Graybar, St. Louis, EC Mag, 2020

Why ‘Materials First’?

There are many challenges that impede the success of construction projects and supply chain chains:

- Inaccurate project estimates,

- Budget overruns,

- Labor challenges,

- Lowballed project timelines,

- Poor site management,

- Slow response to project changes

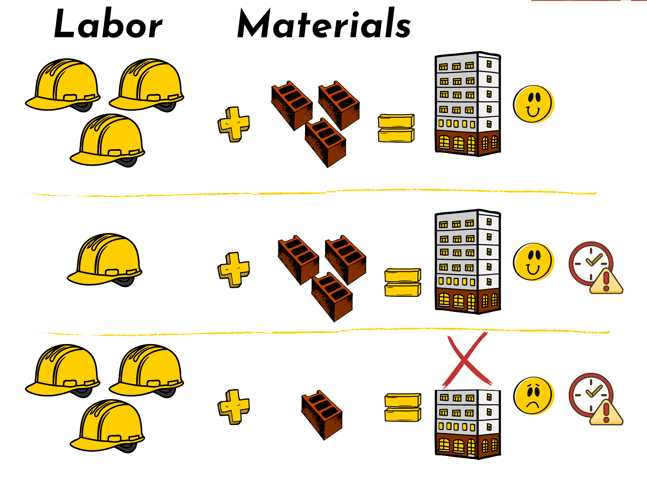

To address these inefficiencies, most solutions in the construction industry focus on labor or productivity-based planning. Though, one of the most overlooked commonalities of these factors is their dependence on material availability in the supply chain. If project materials are not in place when needed, even if labor is ready, it is not possible to complete the project:

While labor planning and productivity are essential to a successful project, materials, are always at the core of a project. This is why we have to start planning and building with the materials first approach.

Data Structures are NOT Built Around Materials

In the current state, construction projects are mainly planned around the labor to get the job done on time and within budget. With that, there are plenty of solutions around the industry that plan labor out very well, in fact, the data applied to material model data may only be used to communicate the labor associated with that particular part of the project and not even communicate the need for that quantity of that material. This leads us to the current problem with materials and material communication. The current data structure in projects is not built out in a manner that satisfies most project material needs.

Why is it Important to Have the Data Structures Around Materials?

The construction industry has been following the ‘this is how we have always done things’ mindset to deliver projects on budget and on time. However, with slow adoption of prefabrication, and the ongoing supply chain challenges, the industry has started to realize the high potential in materials planning. Unfortunately, the current design and modeling (BIM) practices do not output accurate materials data so that the industry could perform effective project and supply chain planning. When the material data is structured and consistent throughout the project life cycle:

- The what and when of materials are more readily available and communicable for contractors.

- Change orders management is simpler for everyone, and there will be less pressure on labor

- Bulk purchases are easier and more accurate, hence will reduce material waste and shortages

- Prefabrication and packaging are easier to adopt and implement at a scale

There is an urgent need for prioritizing the materials for planning projects, supply chain, and procurement. Having material data scattered and not structured has been impeding project timelines. To be able to address the challenges we mentioned earlier and enable industrialized construction, it is important to enhance collaboration between trades and suppliers. The only way to achieve this is to ensure material information flow is right within each supply chain. Unfortunately, trying to make projects more efficient by focusing only on labor or productivity, will not be sufficient anymore. This is why, project and supply chain planning need to be materials first, and this approach needs to be spread across the AEC industry.

.png?width=210&height=65&name=AECInspire-logo_white%20(3).png)