From 0 to 1 – Turning Questions into Schedules

From 0 to 1 – Turning Questions into Schedules

Using AI to Build Real Project Tables That Align Teams

Parts 1 and 2 of this series introduced AI fundamentals and prompting techniques tailored for electrical contractors. In Part 3, we go beyond curiosity and into execution—how AI can deliver structured, actionable schedules that drive decision-making across estimating, detailing, prefab, and field teams.

In electrical construction, the issue isn’t a lack of data—it’s how scattered and siloed that data is. Feeder schedules buried in 1-lines, device callouts hidden in floorplans, and specification details locked in lengthy Division 26 PDFs. Every team—estimating, VDC, project management—ends up building their own disconnected version of the truth.

With [IQ], we can shift that entirely. We're no longer talking about AI as a novelty or assistant. We're using it as a force multiplier to unify stakeholders around a single source of truth. The outcome? Fewer assumptions, tighter plans, and better labor outcomes.

Why Structured Output Changes the Game

Schedules are not just a tool—they are a strategy. In high-stakes electrical construction, structured output is the difference between proactive and reactive decision-making. And when AI generates that structure, it becomes the catalyst for alignment across departments.

Estimators:

Often work with incomplete or overly complex source data. Extracting scope from one-line diagrams and spec books is a manual, error-prone task. With structured output from [IQ], estimators can instantly access:

- Full system layout from main gear to downstream panels

- Voltage and amperage assumptions aligned with spec intent

- Clear conduit and conductor sizing for accurate takeoff

- Identified gaps or ambiguities before bid submission

This shifts estimating from assumption-driven to spec-aligned, giving leadership confidence that what’s priced is what’s built.

Detailers:

Benefit from consistency above all. When devices, feeders, and mounting instructions are summarized in structured tables, they gain:

- Immediate symbol-to-spec correlation

- Visibility into scope gaps that require clarification before layout

- Input-ready formats for prefab design workflows (e.g. device types tied to backbox SKUs)

- Less time spent digging through notes and more time detailing for constructibility

This is how detailing becomes a proactive planning activity—not a reassembly of unclear documents.

Project Managers and Field Leads:

Ue structured schedules to plan manpower, sequence installations, and prevent scope surprises. When AI delivers:

- Conduit IDs with specific run details

- Device installation tables tied to mounting heights and install conditions

- Fully itemized scope by building area or floor

...they can build a labor plan rooted in data—not discovery. The job gets off on the right foot and stays on track.

Yet pulling this data manually across drawings, specs, and submittals is a productivity killer. When [IQ] delivers that same structure in a few minutes, the effect isn’t just time savings—it’s alignment. Alignment between what was bid, what’s detailed, what’s prefabbed, and what gets installed.

The value isn’t in the table—it’s in what that table prevents: missed scope, change orders, coordination delays, and rework.

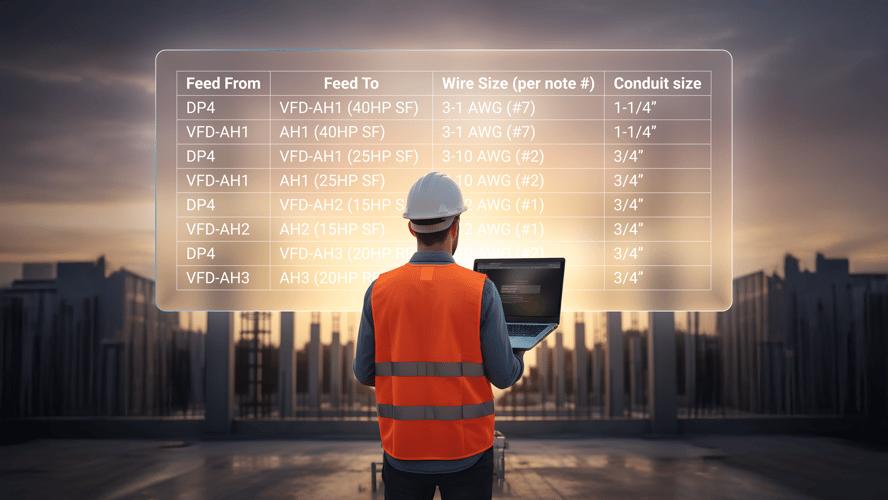

Example: Creating a Feeder Schedule with [IQ]

This prompt structure has helped electrical contractors extract scope clarity from dense design sets:

Prompt

Analyze the electrical one-line diagrams in the provided documents and create a comprehensive table with the following specifications:

Create a table with these exact column headers:

- Conduit ID (use alphanumeric format starting with C001, C002, etc.)

- Equipment ID

- Feed From

- Feed To (list specific equipment names, not general categories)

- Voltage

- Amperage

- Conductor Size

- Conduit Size

- Notes

Requirements:

- Include ALL electrical equipment shown on the one-line diagram

- For "Feed To" column, provide specific equipment names (like "PP1-PP6, CH1-CH2" not "pool equipment")

- Include main service, all distribution panels, transformers, switchboards, major equipment

- Extract voltage, amperage, conductor sizes, and conduit sizes from the diagrams

- Use sequential alphanumeric Conduit IDs (C001, C002, C003, etc.)

- Include any relevant notes about equipment type or location

- Organize rows logically starting with main service and working downstream

Why This Works

This is more than a data request—it’s a project communication tool. Here's what this format enables:

- Sequenced logic: Starting with main service and moving downstream builds a roadmap that mirrors how contractors think and install.

- Naming conventions: Alphanumeric conduit IDs aren’t just neat—they enable prefab labeling, installation prep, and routing strategy.

- Unified scope: Everyone—estimators, VDC, field foremen—can use the same table without translation.

- Context-rich output: With voltage, amperage, and sizing baked in, there's no guessing or checking separate PDFs.

- Time leverage: What used to take 4–6 hours (or days with redlines) is now a 5-minute process—and often with better consistency.

This is the evolution of scope clarity. From something reactive, spreadsheet-driven, and siloed—to something centralized, real-time, and strategic.

Beyond Feeders: Fire Alarm Coordination Matrix

While feeders are foundational, they’re just the tip of the iceberg. Let’s look at how AI can proactively solve design coordination in specialty systems—like fire alarm.

Prompt

Review Sheets FA1.01 through FA1.06. Create a coordination table for fire alarm devices with the following columns:

- Device Type (Smoke Detector, Horn/Strobe, Pull Station, etc.)

- Symbol Used on Plan

- Quantity per Sheet

- Mounting Height (reference Division 28 specifications)

- Installation Notes (ceiling vs wall mount, surface vs recessed, etc.)

The table should include every unique symbol encountered, the sheet it was found on, and reference the mounting requirements as defined in the project specifications. Organize the table by device type, then by plan sheet. Highlight any device types where mounting height or installation method is not clearly defined in the spec.

Why This Works

This isn’t just for prefab teams—it’s a cross-functional planning tool:

- Design validation: You’re validating that the legend, drawings, and specs are in sync—before layout begins.

- Spec extraction: Mounting height data buried in Division 28 now sits right next to the devices it governs.

- QC transparency: If something’s unclear (e.g. no height listed for wall-mounted strobe), that gap is flagged early for RFI.

- Assembly planning: This can tie directly to prefab strategies—wall boxes, backplates, device bundles.

The best part? It builds institutional trust. Teams see the AI surfacing the same questions they’d be asking manually. It doesn’t replace human review—it enhances it by accelerating discovery.

Strategic Prompting Enables Strategic Execution

When contractors hear “AI,” many think of automation or replacement. But that’s not what [IQ] is delivering here. What we’re doing is much more valuable:

- Structuring ambiguity into clarity

- Compressing days of document review into minutes

- Building alignment between departments with one structured output

This is thought leadership in the field—turning disconnected sheets into unified execution plans. Prompting isn’t just a task. It’s the new preconstruction playbook.

.png?width=210&height=65&name=AECInspire-logo_white%20(3).png)