From 0 to 1 – Where It’s All Headed: Agentic AI and the Future of Construction Intelligence

From 0 to 1 – Where It’s All Headed: Agentic AI and the Future of Construction Intelligence

AI isn’t just getting smarter—it’s getting more independent. And that independence has big implications for how we build.

In Parts 1 through 4 of this series, we walked through the early use of AI in construction—prompting to get answers, surfacing project-critical information from floorplans and specs, and transforming that output into schedules, RFIs, and coordination wins.

But where are we headed next? Enter: Agentic AI

Agentic AI isn’t just about answering questions. It’s about AI that reasons, plans, and acts on its own. It performs multi-step tasks, sets internal goals, and executes—sometimes without needing to be asked.

And in electrical construction, that’s a game-changer.

What Is Agentic AI?

Think of today’s AI as your best intern—smart, fast, but waiting for instructions. Agentic AI is your future project coordinator. It doesn’t wait for your prompts—it watches, learns, identifies issues, and takes action.

An Agentic AI system:

- Maintains memory across tasks and documents

- Understands intent, not just keywords

- Plans multi-step actions to reach an outcome

- Takes initiative (e.g., “I see a gap, should I raise an RFI?”)

- Learns from your behavior and decisions to adjust future output

In short: it’s not just reactive, it’s proactive.

And that opens the door to a question every construction leader should be asking: What if your AI could think like your best team member—and act before your team even knew there was a problem?

The Big Shift: From Catching Errors to Preventing Them Entirely

Let’s put this in context. Imagine an agentic system like [IQ] is trained on your project’s sheets, specs, and submittals. It now operates as a second brain for your team. Here’s how:

For Estimators

- Notices changes between addenda and alerts you to revised quantities and equipment

- Suggests likely feeders based on changes to gear locations

- Rechecks spec updates against bid assumptions

- What if your AI could compile your scope clarifications while you estimate, flag high-risk assemblies, and adjust material assumptions in real-time?

For Detailers

- Flags locations where required backboxes or supports are missing

- Warns when routing options violate spec (e.g., MC in non-permitted zones)

- Learns your detailing patterns and begins to suggest early markups

- What if your AI could propose a 90% complete layout before you even begin your sheet markups—using your historical detailing style and project conditions?

For Prefab Managers

- Tracks raceway types and fitting types to auto-generate prefab kit requirements

- Anticipates field installation sequences and proposes prefab build timing

- Identifies material conflicts before kits are assembled

- What if the AI could simulate prefab workflows and suggest labor savings before you commit to a build strategy?

For Project Managers

- Cross-checks submittals for missing product data vs. spec

- Scans for potential RFI issues before the team sees them

- Provides weekly updates of potential scope gaps or schedule risks

- What if your AI could predict which scopes are at risk of delay based on procurement data, unresolved RFIs, and phasing logic—and escalate them before the weekly meeting?

What This Means for Design and Prefabrication

Agentic AI doesn’t just streamline work. It changes what’s possible.

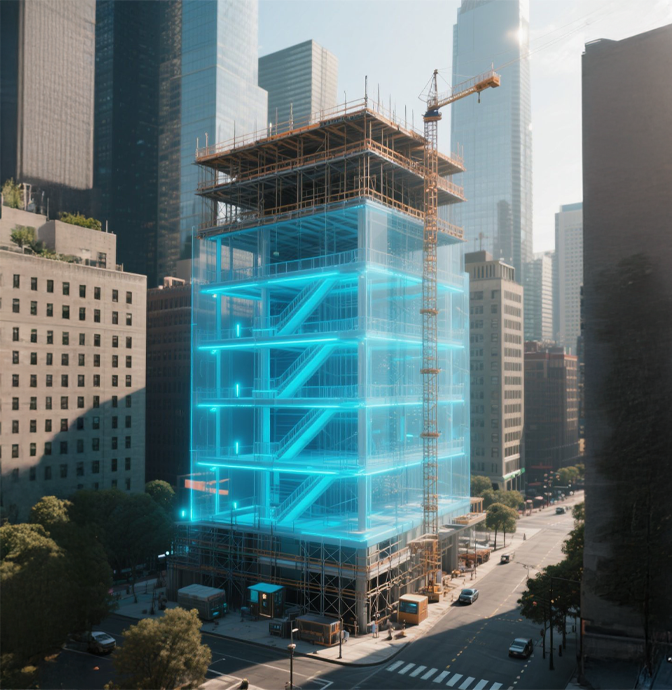

We’re entering an era where AI will actively participate in design interpretation, assembly planning, and constructibility validation.

In AECInspire, we’re already building this into [IQ]:

- AI can walk through a one-line diagram, extract feeders, and propose full schedules.

- It can flag when enclosure ratings don’t match the environmental specs for a given floor or space.

- It can propose assemblies based on available labor skill levels, prefab constraints, and installation conditions.

But let’s push further.

What if your AI could:

- Suggest layout adjustments based on equipment clearance violations?

- Detect coordination problems between ceiling plans and lighting submittals before the clash detection run?

- Generate a complete prefab BOM tied to labor hour estimates and kit configurations?

- What if your AI could predict which scopes are at risk of delay based on procurement data, unresolved RFIs, and phasing logic—and escalate them before the weekly meeting?

This means your prefab plan is no longer just a worksheet—it’s a living recommendation engine, adjusting to phasing changes, spec updates, and field feedback. It’s not waiting for you to say “go”—it’s asking, “Should we prefab this run using aluminum MC instead of EMT to save a week in install time?”

This Is Bigger Than a Tool—It’s a Shift in Mindset

What we’re seeing now is more than just smarter automation. It’s the rise of a proactive construction mindset:

- One where the AI finds issues before the coordination meeting.

- One where the detailing team starts with a proposed layout, not a blank sheet.

- One where every team—from estimating to install—has access to the same live project intelligence.

Agentic AI turns project documents into live, interactive systems. And as we build it into tools like [IQ], it’s not just software—it’s support that scales.

It’s not about telling your team what to do. It’s about giving them a co-pilot that keeps the full project picture in view—even when no one else has time to.

What’s Next

This wraps up our From 0 to 1 series, but the journey is far from over.

Future articles will dive deeper into:

- Scan the full document set, holistically and proactively

- Ask questions that span disciplines, not just divisions

- Preload constructibility into their coordination workflows

If you’ve followed this series, you’re already at the frontier. Because the future isn’t about replacing people—it’s about removing the friction that slows great teams down.

Agentic AI is the next chapter. And if you’re building proactively, it’s one you’ll want to help write.

.png?width=210&height=65&name=AECInspire-logo_white%20(3).png)